China Wholesale Galvanized Stee Wire Rope Manufacturer Factory Quotes - Galvanized steel wire rope 7*7 1.5mm 2.0mm 3.0mm Clothesline rope control cable – Bangyi

China Wholesale Galvanized Stee Wire Rope Manufacturer Factory Quotes - Galvanized steel wire rope 7*7 1.5mm 2.0mm 3.0mm Clothesline rope control cable – Bangyi Detail:

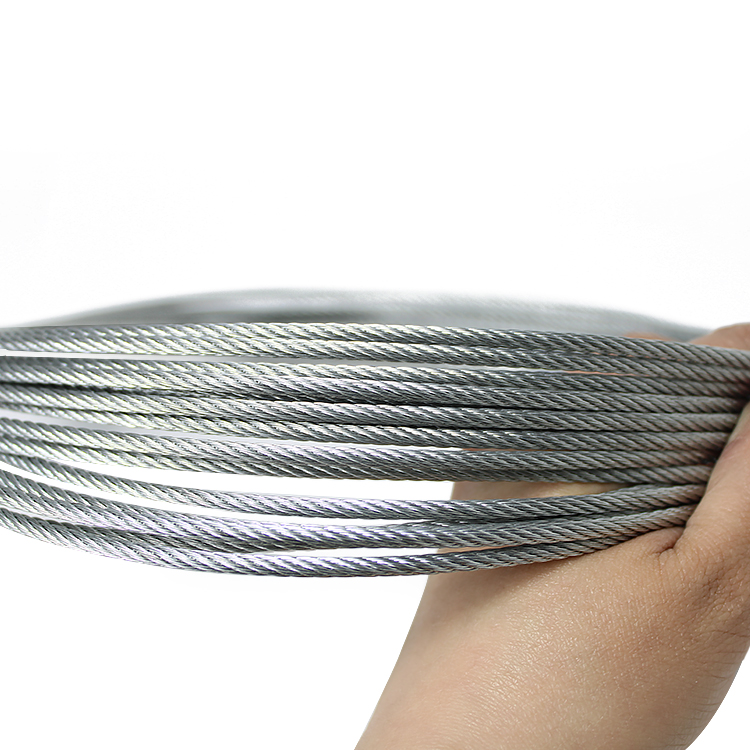

Product Description

Wire rope characteristics:

1. High dimensional accuracy, up to ±0.01mm;

2. Excellent surface quality and good brightness;

3. It has strong corrosion resistance, high tensile strength and fatigue resistance;

4. The chemical composition is stable, the steel is pure, and the content of inclusions is low; the packaging is intact and the price is favorable;

5. Galvanized steel wire rope is made of high-quality carbon structural steel, 60# 65# 70#, etc. The surface can be hot-dip galvanized or electro-galvanized.

6. Steel wire rope packaging: wooden wheel packaging, soft roll packaging.

7. Wire rope application: It has many characteristics such as high temperature resistance, good fatigue resistance, excellent breaking strength, long service life, and durability. It is widely used in coal, petroleum, metallurgy, chemical industry, ships, bridges, electric power, rubber, military industry, and tourism. , Water conservancy, light industry and other industries, products can be produced in accordance with international and foreign advanced standards such as ISO, BS, DIN, JIS, ABS, LR, etc.

Specification

|

Structure |

1*7, 7*7(6*7+FC, 6*7+IWS,6*7+IWRC), 1*19, 7*19(6*19+FC,6*19+IWS,6*19+IWRC), 19*7, etc. |

|

Diameter |

0.3mm –12mm |

|

Material |

Carbon steel 45#,55#,60#,70# |

|

Standard |

DIN, EN, ABS, BS, JIS, LR etc. |

|

T/S |

1570-1960Mpa |

|

Tolerance |

±3% |

| 1*7 | ||||||

| Diameter(mm) | GB/T 20118-2006 GB 8918-2006 |

Approx. weight KG/100M |

EN 12385-4 | Approx. weight KG/100M |

||

| Min. Breaking Load(KN) | Min. Breaking Load(KN) | |||||

| 1770 N/MM² | 1960 N/MM² | 1770 N/MM² | 1960 N/MM² | |||

| 0.3 | 0.09 | 0.10 | 0.05 | — | — | — |

| 0.4 | 0.15 | 0.17 | 0.08 | — | — | — |

| 0.5 | 0.24 | 0.26 | 0.13 | — | — | — |

| 0.6 | 0.34 | 0.38 | 0.19 | 0.308 | 0.347 | 0.18 |

| 0.7 | 0.47 | 0.52 | 0.25 | — | — | — |

| 0.8 | 0.61 | 0.68 | 0.33 | 0.547 | 0.617 | 0.32 |

| 1 | 0.96 | 1.06 | 0.52 | 0.855 | 0.963 | 0.50 |

| 1.2 | 1.38 | 1.52 | 0.75 | — | — | — |

| 1.5 | 2.15 | 2.38 | 1.17 | 1.92 | 2.17 | 1.13 |

| 1.8 | 3.10 | 3.43 | 1.68 | — | — | — |

| 2 | 3.82 | 4.23 | 2.08 | 3.42 | 3.85 | 2.01 |

| 2.5 | 5.97 | 6.62 | 3.25 | 5.34 | 6.02 | 3.14 |

| 3 | 8.60 | 9.53 | 4.68 | 7.69 | 8.67 | 4.52 |

| 4 | 15.29 | 16.93 | 8.32 | 13.70 | 15.40 | 8.03 |

| 5 | 23.90 | 26.46 | 13.00 | 21.40 | — | 12.60 |

| 6 | 34.41 | 38.10 | 18.72 | 30.80 | — | 18.10 |

| 1*19 | ||||||

| Diameter(mm) | GB/T 20118-2006 GB 8918-2006 |

Approx. weight KG/100M |

EN 12385-4 | Approx. weight KG/100M |

||

| Min. Breaking Load(KN) | Min. Breaking Load(KN) | |||||

| 1770 N/MM² | 1960 N/MM² | 1770 N/MM² | 1960 N/MM² | |||

| 0.8 | 0.60 | 0.66 | 0.32 | — | — | — |

| 1 | 0.94 | 1.04 | 0.51 | 0.825 | 0.93 | 0.50 |

| 1.2 | 1.35 | 1.50 | 0.73 | 1.19 | 1.34 | 0.71 |

| 1.4 | 1.84 | 2.04 | 0.99 | — | — | — |

| 1.5 | 2.11 | 2.34 | 1.14 | 1.86 | 2.09 | 1.11 |

| 1.8 | 3.04 | 3.37 | 1.64 | — | — | — |

| 2 | 3.75 | 4.16 | 2.03 | 3.30 | 3.72 | 1.98 |

| 2.5 | 5.86 | 6.49 | 3.17 | 5.15 | 5.81 | 3.10 |

| 3 | 8.44 | 9.35 | 4.56 | 7.42 | 8.37 | 4.46 |

| 3.5 | 11.49 | 12.73 | 6.21 | 10.1 | 11.4 | 6.06 |

| 4 | 15.01 | 16.62 | 8.11 | 13.2 | 14.9 | 7.93 |

| 5 | 23.45 | 25.97 | 12.68 | 20.6 | 23.2 | 12.40 |

| 6 | 33.77 | 37.40 | 18.25 | 29.7 | 33.5 | 17.80 |

| 7 | 45.97 | 50.90 | 24.84 | 40.4 | 45.6 | 24.30 |

| 8 | 60.04 | 66.48 | 32.45 | 52.8 | 59.5 | 31.70 |

| 7*7 | ||||||

| Diameter(mm) | GB/T 20118-2006 GB 8918-2006 |

Approx. weight KG/100M |

EN 12385-4 | Approx. weight KG/100M |

||

| Min. Breaking Load(KN) | Min. Breaking Load(KN) | |||||

| 1770 N/MM² | 1960 N/MM² | 1770 N/MM² | 1960 N/MM² | |||

| 1.2 | 0.92 | 1.01 | 0.56 | 0.99 | 1.10 | 0.56 |

| 1.4 | 1.25 | 1.38 | 0.76 | 1.35 | 1.49 | 0.76 |

| 1.5 | 1.43 | 1.58 | 0.87 | 1.55 | 1.71 | 0.87 |

| 1.8 | 2.06 | 2.28 | 1.25 | 2.23 | 2.46 | 1.25 |

| 2 | 2.54 | 2.81 | 1.55 | 2.75 | 3.04 | 1.55 |

| 2.5 | 3.97 | 4.40 | 2.42 | 4.29 | 4.75 | 2.42 |

| 3 | 5.72 | 6.33 | 3.48 | 6.18 | 6.84 | 3.48 |

| 3.5 | 7.78 | 8.62 | 4.74 | 8.41 | 9.32 | 4.74 |

| 4 | 10.17 | 11.26 | 6.19 | 10.99 | 12.17 | 6.19 |

| 4.5 | 12.87 | 14.25 | 7.84 | 13.91 | 15.40 | 7.84 |

| 5 | 15.89 | 17.59 | 9.68 | 17.17 | 19.01 | 9.68 |

| 5.5 | 19.22 | 21.29 | 11.71 | 20.77 | 23.00 | 11.71 |

| 6 | 22.88 | 25.33 | 13.93 | 24.72 | 27.38 | 13.93 |

| 7 | 31.14 | 34.48 | 18.96 | 33.65 | 37.26 | 18.96 |

| 8 | 40.67 | 45.03 | 24.77 | 43.95 | 48.67 | 24.77 |

| 7*19 | ||||||

| Diameter(mm) | GB/T 20118-2006 GB 8918-2006 |

Approx. weight KG/100M |

EN 12385-4 | Approx. weight KG/100M |

||

| Min. Breaking Load(KN) | Min. Breaking Load(KN) | |||||

| 1770 N/MM² | 1960 N/MM² | 1770 N/MM² | 1960 N/MM² | |||

| 3 | 5.29 | 5.86 | 3.6 | 5.77 | 6.39 | 3.6 |

| 3.2 | 6.02 | 6.66 | 4.1 | 6.56 | 7.27 | 4.1 |

| 3.5 | 7.20 | 7.97 | 4.9 | 7.85 | 8.69 | 4.9 |

| 4 | 9.40 | 10.41 | 6.4 | 10.25 | 11.35 | 6.4 |

| 5 | 14.7 | 16.3 | 10.0 | 16.02 | 17.74 | 10.0 |

| 6 | 21.2 | 23.4 | 14.4 | 23.07 | 25.54 | 14.4 |

| 7 | 28.8 | 31.9 | 19.6 | 31.40 | 34.77 | 19.6 |

| 8 | 37.6 | 41.6 | 25.6 | 41.01 | 45.41 | 25.6 |

| 9 | 47.6 | 52.7 | 32.4 | 51.90 | 57.47 | 32.4 |

| 10 | 58.8 | 65.1 | 40.0 | 64.07 | 70.95 | 40.0 |

| 11 | 71.1 | 78.7 | 48.4 | 77.53 | 85.85 | 48.4 |

| 12 | 84.6 | 93.7 | 57.6 | 92.27 | 102.17 | 57.6 |

| 13 | 99.3 | 110.0 | 67.6 | 108.29 | 119.91 | 67.6 |

| 14 | 115.2 | 127.5 | 78.4 | 125.59 | 139.07 | 78.4 |

| 15 | 132.2 | 146.4 | 90.0 | 144.17 | 159.64 | 90.0 |

| 16 | 150.4 | 166.6 | 102.4 | 164.03 | 181.64 | 102.4 |

| 19*7 | ||||||

| Diameter(mm) | GB/T 20118-2006 GB 8919-2006 |

Approx. weight KG/100M |

EN 12385-4 | Approx. weight KG/100M |

||

| Min. Breaking Load(KN) | Min. Breaking Load(KN) | |||||

| 1770 N/MM² | 1960 N/MM² | 1770 N/MM² | 1960 N/MM² | |||

| 3 | 5.2 | 5.8 | 3.9 | 5.2 | 5.8 | 3.6 |

| 4 | 9.3 | 10.3 | 6.9 | 9.3 | 10.3 | 6.4 |

| 5 | 14.5 | 16.1 | 10.8 | 14.5 | 16.1 | 10.0 |

| 6 | 20.9 | 23.1 | 15.5 | 20.9 | 23.1 | 14.4 |

| 7 | 28.4 | 31.5 | 21.1 | 28.4 | 31.5 | 19.6 |

| 8 | 37.2 | 41.1 | 27.5 | 37.2 | 41.1 | 25.7 |

| 9 | 47.0 | 52.1 | 34.8 | 47.0 | 52.1 | 32.5 |

| 10 | 58.1 | 64.3 | 43.0 | 58.1 | 64.3 | 40.1 |

| 11 | 70.2 | 77.8 | 52.0 | 70.2 | 77.8 | 48.5 |

| 12 | 83.6 | 92.6 | 61.9 | 83.6 | 92.6 | 57.7 |

| 13 | 98.1 | 109 | 72.7 | 98.1 | 108.6 | 67.8 |

| 14 | 114 | 126 | 84.3 | 114 | 126 | 78.6 |

| 15 | 131 | 145 | 96.8 | 131 | 145 | 90.2 |

| 16 | 149 | 165 | 110.1 | 149 | 165 | 102.7 |

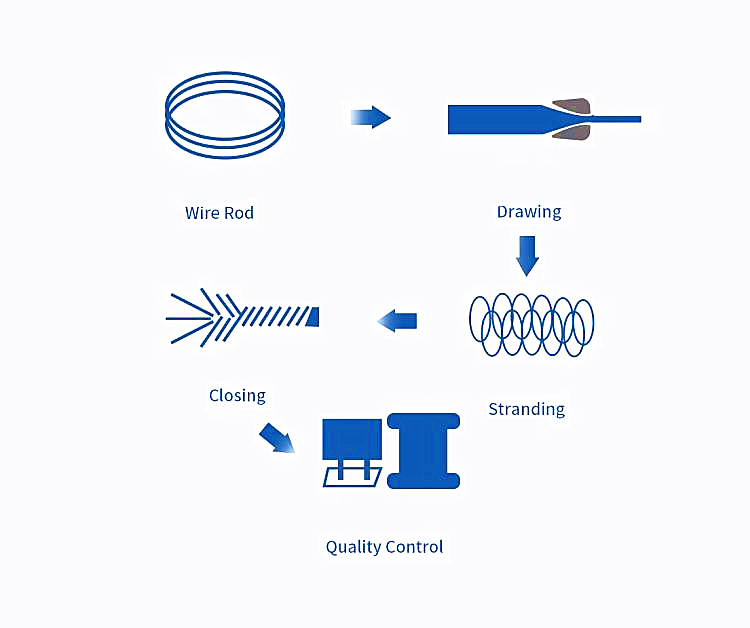

Production Process

Applications

1. Security seals.

2. Towing, pulling, strapping.

3. Fence, greenhouse, door pipe,green house.

4. Low pressure liquid, water, gas, oil, line pipe.

5. For both indoor and outdoor the building construction.

6. Widely used in scaffolding construction which is much cheaper and convenient.

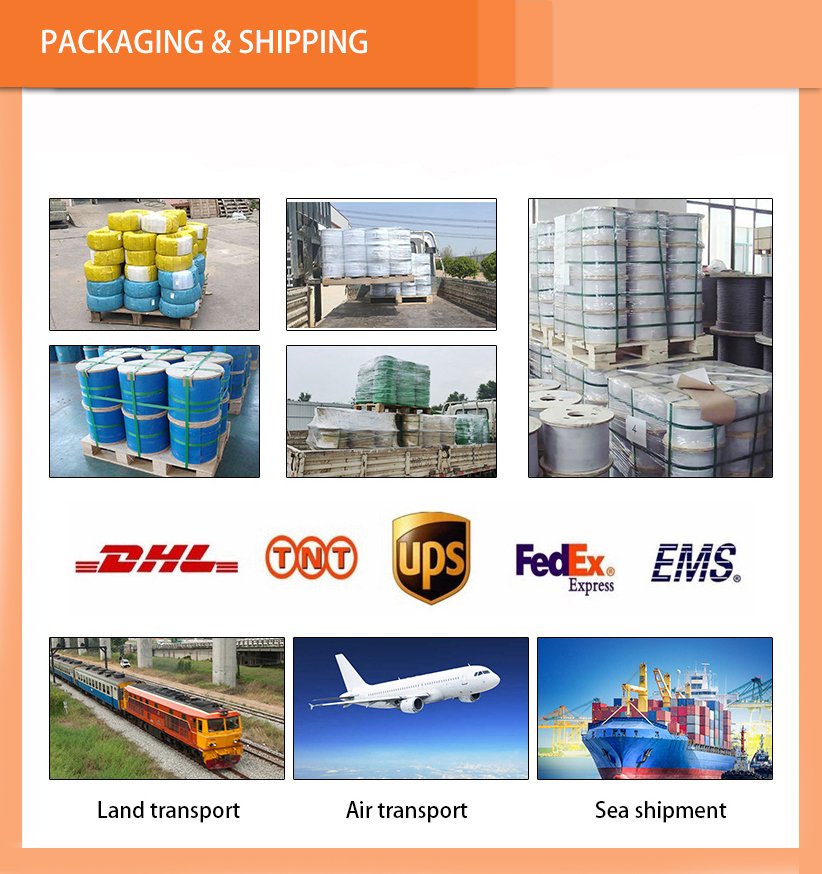

Packing

Packing: Wooden reel, iron reel, plastic reel, flexible reel,custom packaging.

Shipping: We support international express for your sample order: Like TNT, DHL, FedEx, UPS, EMS, etc. We shipping the bulk order by Sea, by train, etc.

Produce time: Within 3-15 working days.

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for China Wholesale Galvanized Stee Wire Rope Manufacturer Factory Quotes - Galvanized steel wire rope 7*7 1.5mm 2.0mm 3.0mm Clothesline rope control cable – Bangyi , The product will supply to all over the world, such as: Montreal, Netherlands, Estonia, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.