Europe style for Wholesale Pvc Coated Stainless Steel Cable - Stainless Steel Wire Rope2 – Bangyi

Europe style for Wholesale Pvc Coated Stainless Steel Cable - Stainless Steel Wire Rope2 – Bangyi Detail:

Product Description

Stainless steel wire rope use high-quality AISI304, AISI316 as stainless steel raw materials. It has excellent corrosion resistance, high temperature resistance and low temperature resistance. It is widely used in petrochemical industry, aviation, automobile, fishing, building decoration and other industries. After electrolytic polishing, the stainless steel wire rope becomes bright and the corrosion resistance feature is greatly enhanced.

Stainless steel wire rope adopt fully automated production lines . The production process consists of wire drawing, stranding and closing. Wire drawing is to draw a thick steel wire rod into thin wire. Stranding is to synthesize wire into strands, and closing is to reshape strands into rope. After these three processes are completed, they undergo quality inspection, packaging, and finally become a finished product .

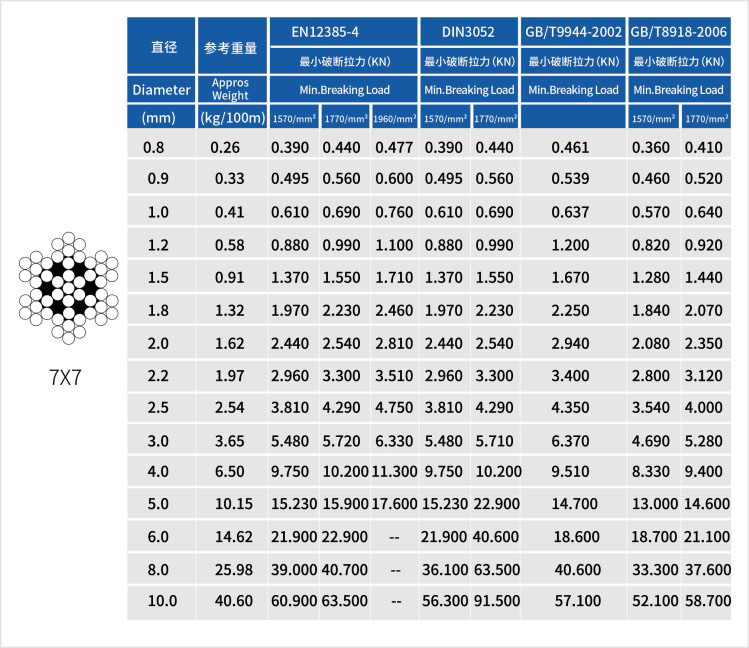

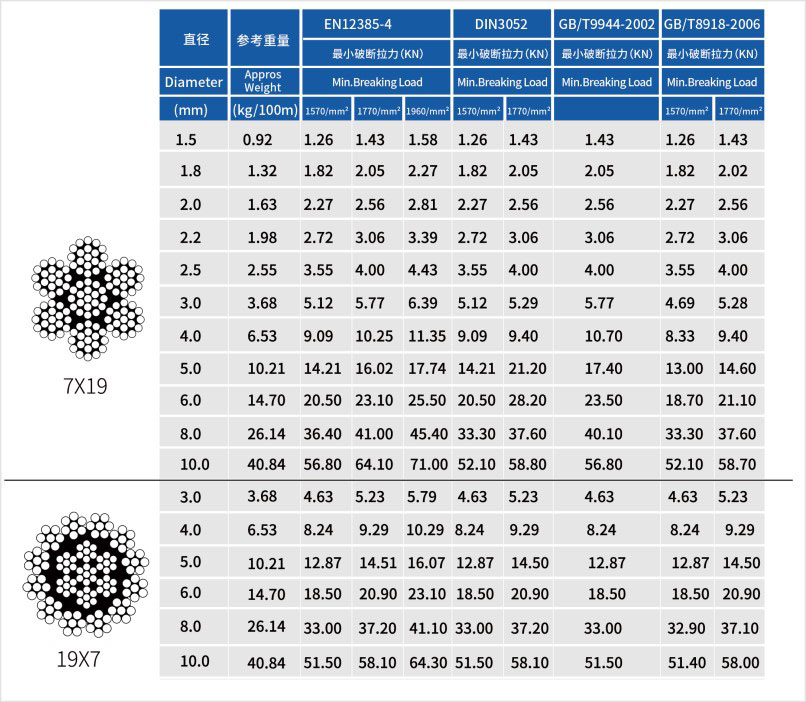

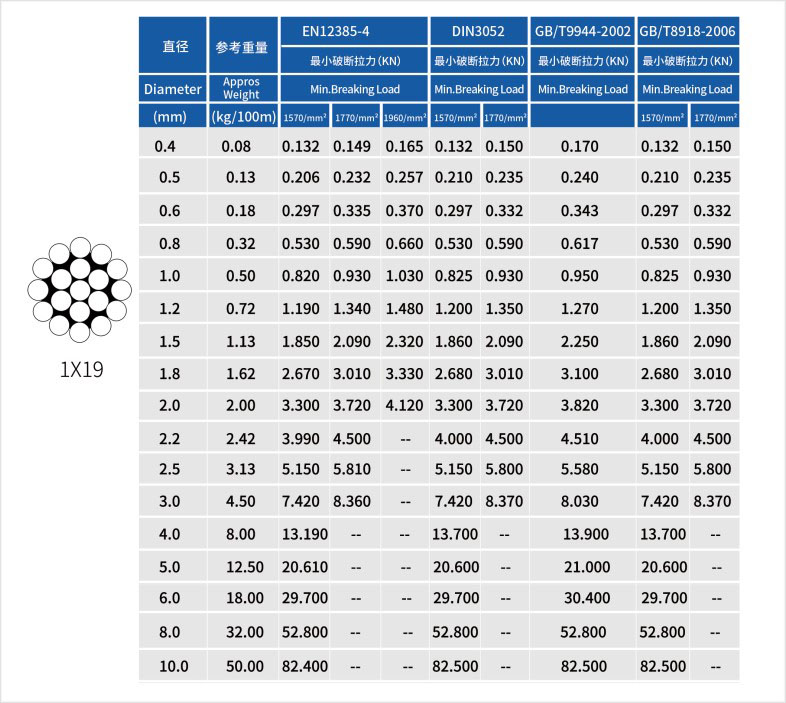

Stainless steel wire rope use high-quality AISI304, AISI316 stainless steel as raw materials. with many or many strands of fine wire twisted into a flexible rope. Stainless steel wire rope adopt fully automated production lines . The production process consists of wire drawing, stranding and closing. Wire drawing is to draw a thick steel wire rod into thin wire. Stranding is to synthesize wire into strands, and closing is to reshape strands into rope. After these three processes are completed, they undergo quality inspection, packaging, and finally become a finished product. Main specifications: 1X7, 7X7, 6X7+FC, 6X7+IWRC, 1X19, 7X19, 6X19+FC, 6X19+IWRC. (Fiber Core (FC):This core is made of either natural fibres or polyroplylene and provides excellent elasticity.In addtion,the fibre core is impregnated with lubricant during manufacture.It is thereby lubricated internally thus reducing internal corrosion and wear between wires.) , (Independent Wire Rope Core (IWRC): This core is usually composed of a sepate7*7 wire rope around which wire strands are laid.The steel core increases the strength by7%and the weight by10%.These steel cores provide more substantial support than fibre cores to the outer strands during the rope’s operating life thus ensuring even stress distribution and retention of the rope shape.Steel centres resist crushing,distortion and are more resistant to heat and increase the strength of the rope.), The lay direction can be right (symbol Z) or left (symbol S), Stainless steel wire Rope can be produced in accordance with GB/T 9944-2015, ISO, BS, DIN, JIS, ABS, LR and other international and foreign advanced standards. Min tensile strength 1770mpa, 1570mpa, 1670mpa, 1860mpa, 1960mpa.

Stainless Steel Wire Rope has excellent corrosion resistance able to work normally in the harsh environment of various harmful media, high temperature resistance and low temperature resistance,Able to withstand various loads and variable loads.

It has high tensile strength, fatigue strength and impact toughness.

Under high-speed working conditions, it is abrasion-resistant, shock-resistant and stable in operation.

Good softness, suitable for traction, pulling, strapping and other purposes. It is widely used in wire drawing, weaving ,hose,wire ropes, filtration equipment, steel strand, spring, electronic instruments, medical treatment, Anti-theft devices, Labor protection, Grain nail,etc

Application

Specification

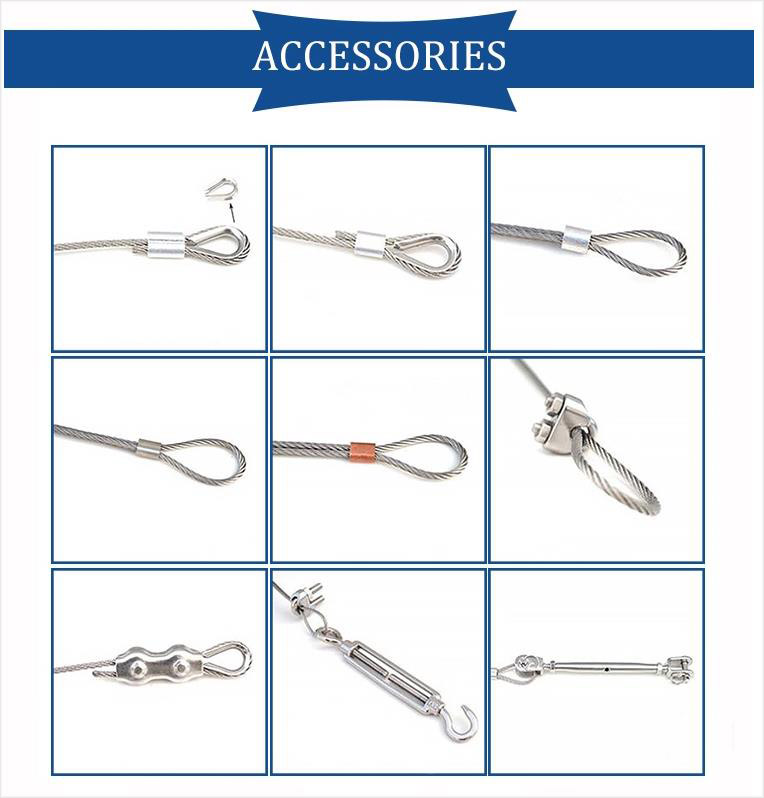

Product detail pictures:

Related Product Guide:

High quality Very first,and Consumer Supreme is our guideline to offer the most beneficial service to our consumers.At present, we're attempting our greatest to be among the top exporters in our area to fulfill buyers far more need to have for Europe style for Wholesale Pvc Coated Stainless Steel Cable - Stainless Steel Wire Rope2 – Bangyi , The product will supply to all over the world, such as: Brisbane, Leicester, Peru, We've got a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will absolutely benefit in both short and long run.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!