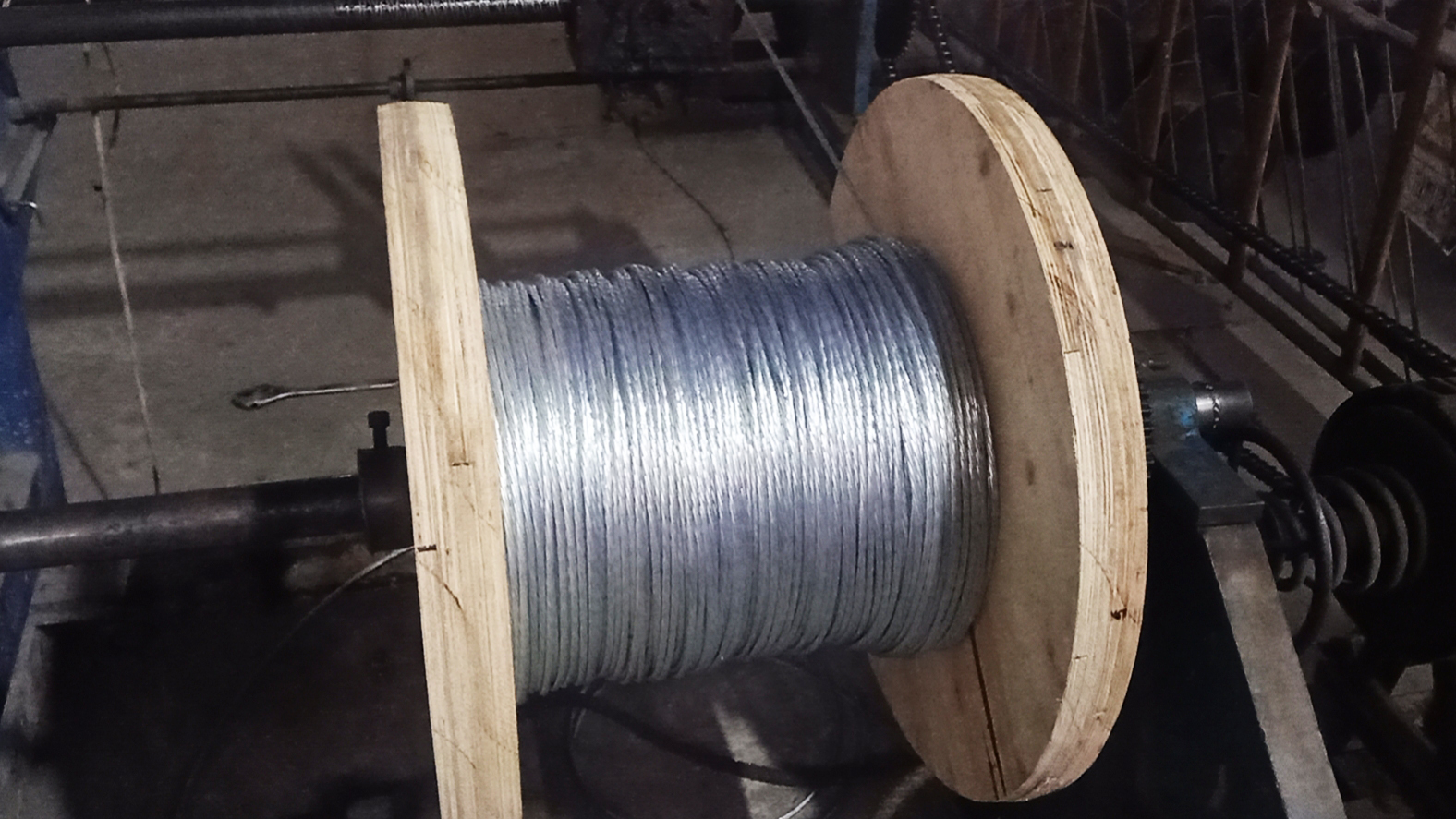

Galvanized steel strand is a steel product made up of multiple galvanized steel wires twisted together.

Product application

Galvanized steel strand is usually used for messenger wire, guy wire, core wire or strength member, etc. It can also be used as an earth wire/ground wire for overhead transmission, a barrier cable on both sides of a highway, or a structure cable in a building structure. The commonly used prestressed steel strand in prestressed steel strand is uncoated steel strand for prestressed concrete, and it is also galvanized. It is commonly used in bridges, construction, water conservancy, energy and geotechnical engineering, etc., unbonded steel strand or monostrand is commonly used in floor slab and foundation engineering Wait.

Related standards

YB/T5004-1993 galvanized steel strand

YB/T098-1997 Galvanized Steel Stranded Wire for Optical Cable

YB/T5004-2001 galvanized steel strand

Features: 1. Good flexibility 2. Good stability 3. Good reliability 4. High strength

Classification

a. Steel strands are divided into four types according to the cross-sectional structure? As shown in the figure below.

Structure 1×3 1×7 1×19 1×37

b. According to the nominal tensile strength of the national standard steel stranded wire, it is divided into five grades: 1270MPa, 1370MPa, 1470MPa, 1570MPa, and 1670MPa.

c. According to the thickness of the steel wire zinc layer in the galvanized steel strand, the grade of the steel wire zinc layer in the national standard steel strand is divided into three levels: A, B, and C.

Folding stranding process requirements

1. The steel wire (including the center wire) of the steel strand should be the same diameter, the same strength, and the same zinc layer level.

2. The diameter and lay length of the steel strands should be uniform. They should not be loose after being cut.

3. The steel wires in the steel strand should be tightly twisted, and there should be no staggering, breaking or bending.

4. The steel stranded wire should be straight, soft, with low residual stress, and should not be deformed after unfolding.

5. 1×3 structural steel stranded wire and overhead ground wire are not allowed to be jointed. The inner steel wire joints of other types of steel stranded wire shall be connected by electric welding. The distance between any two joints shall not be less than 50m and the joints shall be treated with anti-corrosion treatment.

Post time: Dec-10-2021