There are many processes for galvanizing steel strands, but the most common and commonly used are hot-dip galvanizing and electro-galvanizing.

Hot-dip galvanized steel strand:

Hot-dip galvanizing, also known as hot-dip galvanizing and hot-dip galvanizing, is an effective method of metal anti-corrosion. , so as to achieve the purpose of anti-corrosion. Hot-dip galvanizing has good coverage, and the resulting coating is thick and dense. After a long time of use, even if it is damaged by oxidation, a protective film will continue to be formed to protect the inside. Hot-dip galvanizing is made of older hot-dip galvanizing. method developed.

Electro-galvanized steel strand:

Electroplating is a process of attaching a metal film to the surface of metal or other materials by electrolysis, so as to prevent oxidation and corrosion of steel strands, and can improve wear resistance, electrical conductivity, light reflection, copper sulfate resistance, etc. Corrosive and enhance the appearance and other effects. The electro-galvanized layer is thinner, mainly to enhance the corrosion resistance of steel strands, increase hardness, prevent abrasion, improve conductivity, smoothness, heat resistance and surface beauty.

The main difference between the two is:

To put it simply, the production process of hot-dip galvanizing is more complicatedthan that of steel strands, the zinc layer is evenly distributed, the amount of zinc applied is higher, and the resulting coating is thicker. It has a long service life, so it is an important protective coating for steel parts used in harsh working environments, and it is widely used.

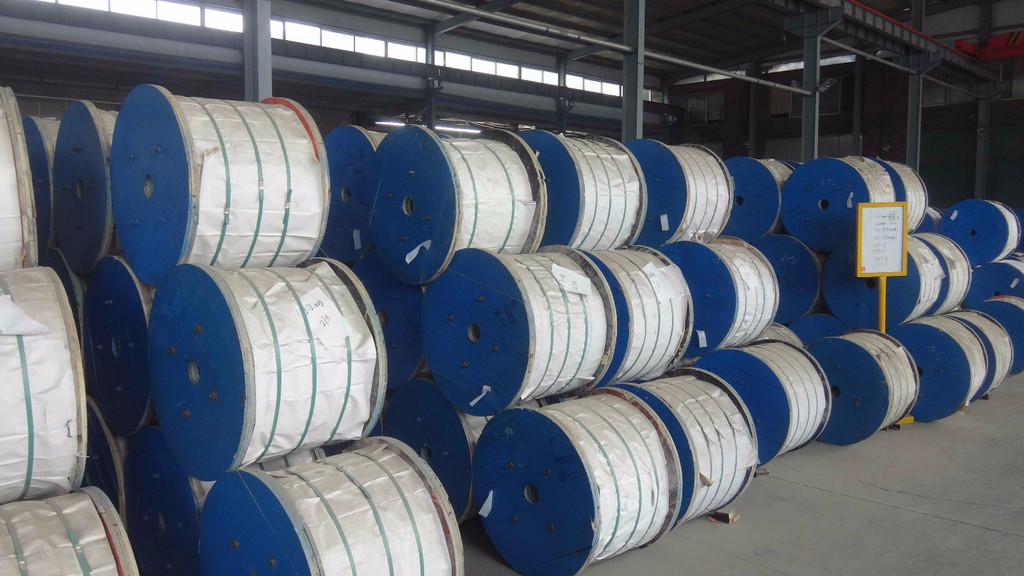

The use of hot-dip galvanized steel strands is very large, as we all know, can be widely used in construction, industry, agriculture, aquaculture, mining, petroleum, chemical industry, garden protection, food processing, transportation and other fields. Binding, fixing, box cages, net pads, protective nets, fences, paper baskets, artworks, etc.

Post time: Apr-08-2022