1. There are many advantages to using steel wire rope instead of other ropes:

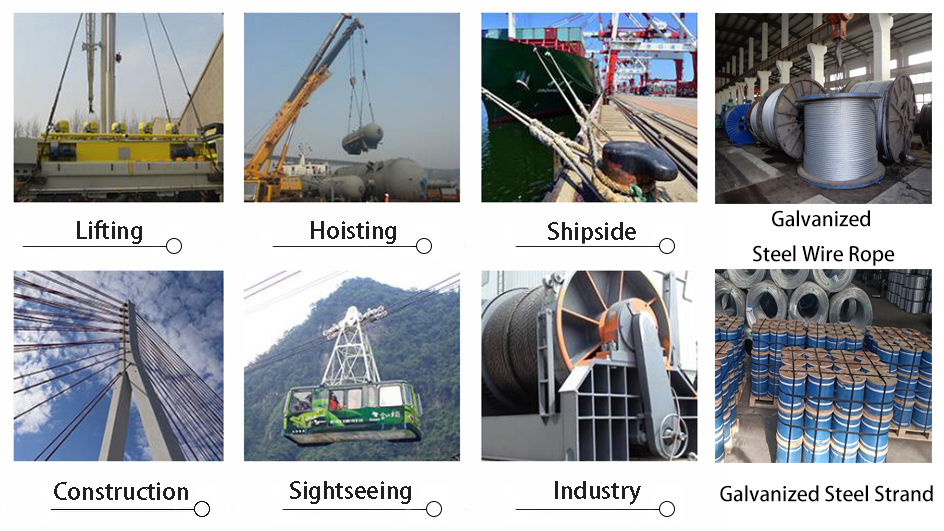

In the process of industrial production, the rope is one of the necessary tools, and the most widely used rope should be the steel wire rope. Used for lifting, towing, lashing, high-altitude transportation, etc., the rope is so popular because of its many unique benefits.

① It has a higher safety factor than other ropes, and there is no problem even with long-distance load.

②Its light weight makes it very convenient to carry and use.

③This kind of steel wire rope has strong tensile strength and high toughness, and will not break suddenly during use, resulting in serious consequences.

④ In the process of high-speed operation, the wear resistance is good, and the flexibility will not be twisted, which is relatively stable. Because of this characteristic, it is used in the operation of the elevator.

⑤Corrosion resistance, chemical reaction is not easy to occur when working in a harmful environment, and the service life is long. Sixth, it is a combination of firmness and softness, which can be used for binding, pulling, dragging, etc., and has a wide range of uses.

2. Pay attention to the load-bearing and breaking force of the steel rope and choose the appropriate product:

Don’t think that just because this material is called wire rope, it is omnipotent. In fact, if you choose the wrong type, in some cases, its security risks may be greater. For example, the load-bearing capacity of ropes of different diameters varies greatly depending on the weaving method. Under normal circumstances, after the rope is selected, it is not allowed to increase the weight of the hoisting casually.

Similar to ordinary steel, when the load-bearing capacity exceeds the load-bearing capacity, the wire rope will deform obviously or not. Generally speaking, thick ropes are less prone to deformation than thin ropes. However, thick ropes may be twisted and broken without special treatment. This is also the reason why the rope is not the thicker the better.

What diameter rope to choose, usually at the beginning of the construction, experts will give a plan. It is strictly forbidden to violate the plan without aggravating the project. You must know that the safety hazards of high-altitude hanging objects are very large. Once a rupture occurs, it may cause a major or even a catastrophic accident.

3. What are the secrets of maintenance of steel wire ropes for lifting:

Wire ropes are used very frequently in our lives, and at the same time, they feel very hard and reliable to us, but if they are not properly maintained, the service life will be shortened, the cost of use will be increased, and there will also be certain safety hazards. , so good maintenance can prolong the service life of the wire rope and improve the safety factor.

①The maintenance of the wire rope needs to pay attention to the usual loading and unloading. The loading and unloading project is a key to the maintenance of the steel wire rope. When loading and unloading, try to use lifting equipment or professional skateboard tools for loading and unloading, so as to avoid the disorder of the rope reel, resulting in wire wear or damage. entanglement phenomenon.

②During the transportation of the steel wire rope, avoid rolling on the uneven ground, which is easy to cause damage to the steel wire dial. At the same time, when rolling, it is easy to stick some stones or clay, etc., which will also affect the steel wire rope. use. In the process of winding the wire rope, it is necessary to pay more attention to the directionality. It is necessary to wind and release the rope in a certain direction.

Post time: Mar-17-2022