Wire Rope Terms

Breaking Strength – A calculation of the load necessary to break a wire rope that is in tension.

Core – Element of a wire rope around which the strands are helically laid. The core could be made of fiber (cloth), independent wire rope or wire strand.

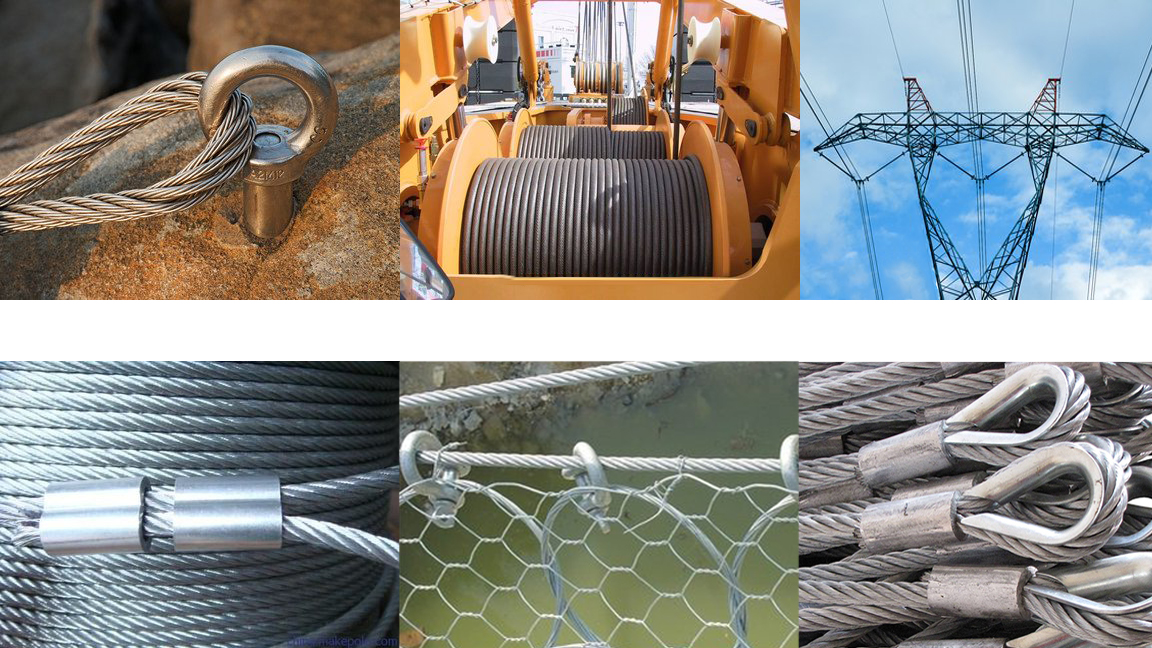

Drum – A round and flanged barrel, which is tapered or uniform in diameter for storage or operation, around which rope is wound.

Extra Improved Plow Steel – Steel that is designed for applications, which require greater safety features with no increase in diameter size and the highest resistance to abrasive wear. This steel is fifteen percent stronger than Improved Plow Steel, and the tensile strength of this grade ranges from 280,000 to 340,000 psi.

Galvanize – To coat with zinc for the protection of the wire, strand or rope from corrosion.

Grade – A classification according to breaking strength.

Guy Line – Steel wire or strand, typically galvanized, that braces or supports a structure.

Improved Plow Steel (IPS) – A high-carbon steel having a tensile strength of approximately 260,000 psi that is roughly fifteen percent stronger than Plow Steel. Most commercial wires are made from IPS.

Independent Wire Rope Core (IWRC) – Wire rope that serves as the core for a greater rope.

Iron – A low carbon steel wire of approximately 10,000 psi, which is pliable and capable of repeated stresses from bending around small sheaves. This grade is effective for tillers, guys and sash ropes.

Lay/Laid – The manner in which the wires are helically wound to form rope. Lay refers specifically to the direction of the helical path of the strands in a wire rope; for example, if the helix of the strands are like the threads of a right-hand screw, the lay is known as a right lay, or right-hand, but if the strands go to the left, it is a left lay, or left-hand.

Marine Rigging – is used on commercial and recreational boats for a variety of purposes. Cables of various sizes are used to secure masts, hoist sails, tie boats up next to a dock, and hold cargo in place during transport.

Mechanical Cable Assemblies – Heavy duty mechanical cable assemblies are used in a variety of industrial equipment applications to pull objects and bear large amounts of weight at any given time. Mechanical cable assemblies can also be used for much smaller applications like the brakes on a normal bicycle or the throttle pulley on a car.

Rope Grades – A classification of wire rope according to its breaking strength. The rank of grades according to increasing breaking strengths is as follows: Iron, Traction, Mild Plow Steel, Plow Steel, Improved Steel, Extra Improved Steel.

Rigging Equipment – Used on sail boats to secure masts and move sails as needed. Cables of various sizes are used on the rigging to stiffen the mast in the wind, hoist the sails, tie boats up next to a dock, and even hold cargo in place during transport.

Sheave – A pulley wheel with a channel, mounted in a frame, that guides or alters the direction of the cable or rope.

Strand – An assembly of wires that are helically wound around an axis, fiber or wire center (core) to create a symmetrical portion.

Strand Grades – Classification of strands according to breaking strength. The ranking of increasing breaking strengths is as follows: Common, Siemens Martin, High Strength and Extra-High Strength; a utility’s grade strand is available for certain requirements.

Swage – The act of fastening a termination to a wire rope through physical deformation of the termination about the rope via a hydraulic press or hammering. The strength is one hundred percent of the wire rope rating.

Swaged Fittings – Fittings into which wire rope can be inserted and fastened through a cold flow method.

Traction Steel – A grade of rope material that has a tensile strength range of 180,000 to 190,000 psi. Traction steel has great resistance to bending fatigue with a minimum of abrasive force on sheaves and drums, which contributes to its long use in elevators, from which the steel gets its name.

Wire – A continual span of metal that has been cold drawn from a rod.

Wire braids – It is composed of wire strands that are braided together. Wire braid is similar to stranded wire. The difference between the two is the fact that stranded wire features strands that are bundled together, rather than braided.

Wire Rope Fittings – essential parts of cable assemblies, wire rope assemblies and wire rope slings that assist spliced or swagged rope ends in connecting to other cables and keeping cables and rope from unraveling.

Wire Rope Cable Assemblies – A wire rope cable assembly is a metallic rope consisting of bundles of twisted, spiraled, or bonded wires. While the terms wire rope and cable are often used interchangeably, cables are typically designated as smaller diameter wire ropes, specifically wire ropes with a diameter less than 3/8 inch. Therefore, wire rope cable assemblies are typically utilized for lighter duty applications.

Wire Rope Lanyards – or cable assemblies, are cables which are comprised of many spiraled bundles of wire. These cables are used to support hanging objects, connect objects, pull or lift objects, secure items, and much more.

Post time: Aug-24-2021